Emerging issues and market trends

As a service provider working across a diverse group of industries, Downer’s capability and agility enables us to respond to a wide variety of market trends. Below is a sample of the services we provide in response to emerging issues and market trends.

Waste, recycling and the circular economy

FY18 has seen China’s National Sword Policy come into effect triggering a strong interest from industry, government and among the general public in waste, recycling and the circular economy with a particular focus on problem wastes such as plastics. Downer’s use of waste materials such as glass and printer cartridge toner within its road asphalt products divert these products from landfill.

Downer's use of waste materials such as glass and printer cartridge toner within its road asphalt products divert these products from landfill. Downer has further increased its recycling footprint with the introduction of a new asphalt product, made from recycled plastic, and the construction of the Rosehill Detritus Plant which receives street sweepings and processes the material into several recycling streams.

Downer has further increased its recycling footprint with the introduction of a new asphalt product, made from recycled plastic, and the construction of the Rosehill Detritus Plant which receives street sweepings and processes the material into several recycling streams.

The NZ Spotless laundries team reallocates approximately 35 tonnes of scrap linen each year, by selling or distributing to avoid ending up in landfill. The Dandenong laundry team also donated tens of thousands of linen items to the Taveuni Island Health Care Network in Fiji, through the aid of Boronia Rotary Club and Rotary New Zealand World Community Service.

Downer is a leading manufacturer and supplier of bitumen based products, providing our customers with asphalt, blended binders and emulsion products. Downer continues to be an innovator in the sustainable asphalt industry, running plants that use recyclable products and environmentally sustainable methods to produce asphalt. In FY18, 12.71 per cent of total asphalt production in Downer was made up of recycled materials.

Please visit this page on your computer for access to trends data

Infrastructure rating tools

Customers are increasingly specifying ratings for their projects which present us with challenges and opportunities. The application of sustainability rating tools for nominated infrastructure projects allows us to address, mitigate and manage climate-related risks.

Some of Downer’s successes in infrastructure sustainability include:

- Ararat Wind Farm - the first renewable project to gain an ISCA rating to complement the Whitsunday water treatment plant which was the first Design and As Built rating to achieve an Excellent rating, and the first operational rating at a water treatment plant at the iconic MCG

- Newcastle Light Rail – great outcomes around heritage components of the project.

Growth in the renewables industry

Downer remains one of the largest and most experienced providers of design, build and maintenance services to Australia’s renewable energy market and 2017 was a record year for renewables growth in Australia with 4,670 MW of new generation capacity added6. In FY18 Downer had 576 MW of solar and wind under construction. In addition, Downer increased renewable energy consumption to 2,141 GJ in its own operations primarily from Solar PV on rail maintenance, laundries and educational facilities. For example, Cardiff Rail Maintenance Facility commissioned a 100kW solar PV system to offset grid consumption.

Decarbonising our fleet

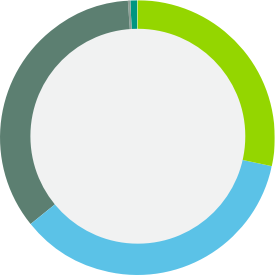

Reducing the carbon emissions of fleet is a challenge for many businesses with the switch to low emission and electric vehicles an increasingly available option. At Downer transport fuel (road registered vehicles) accounts for 37 per cent of our carbon emissions, so reducing fuel consumption is key to our carbon strategy. At Downer, liquid fuel such as diesel oil accounts for 61 per cent of our carbon emissions, so reducing fuel consumption is key to our carbon strategy.

Influenced by the NZ Government's incentives for electric vehicles, Downer's New Zealand business has had four electric vehicles (EVs) operating across the business since 2016, covering 25,000 kilometres and saving 4.8 tCO2-e. A combination of fleet upgrades and installation of EROAD Drive Buddy resulted in 638 tCO2-e in fuel savings in FY18.

In Australia the Mining, Energy and Industrial Division purchased four PHEV (plug in hybrid electric vehicles) to trial. The Roads business has saved 2,650 tCO2-e per annum in diesel in FY18 by upgrading vehicles and rollers.

Increasing use of technology

Automation and the increasing use of technology in the workplace, industry and community is a fact of modern life. Examples of Downer's engagement with smart and automated solutions include:

- Smart Stormwater Drains

- In the first project of its kind in Victoria, KeolisDowner is trialling an autonomous shuttle bus in Melbourne's north at La Trobe University's Bundoora campus

- As a transport infrastructure service provider Downer is a partner in the Sustainable Business Australia (SBA) Sustainable Mobility Project, a cross-sector collaboration ‘to lead an Australian business response to the challenges and opportunities of meeting Australia's mobility needs more sustainably’.

6 https://www.cleanenergycouncil.org.au/news/2018/February/reflecting-record-year-renewables.html