Resource management

Downer is committed to reducing the environmental footprint of the products we provide to our customers. Emissions is one component of this. Natural resource usage is another and Downer is committed to the principles of the circular economy, including understanding products’ lifecycles to ensure that their burden on the natural environment is kept to the lowest possible level.

The demand from our customers, communities, industry and government for circular economy thinking to reduce waste continues to be an important issue and growth opportunity.

Downer demonstrates our commitment to the circular economy in the following ways:

- Investment in our Reconomy and Repurpose It businesses

- Waste materials such as hard and soft plastics, glass and printer cartridge toner used in our road asphalt products in Australia and New Zealand, diverting these products from landfill

- Development and marketing of Reconophalt™, a Downer product which incorporates recycled soft plastics and glass into asphalt road construction. Reconophalt is Australia’s first asphalt product containing high-recycled content derived from true waste streams that would otherwise be bound for landfill. Materials are sourced through Downer’s exclusive partnership with Close the Loop, Downer’s own detritus repurposing facilities, and other suppliers of recycled resources.

Following 18 months of extensive testing under a program designed in conjunction with the New South Wales Environment Protection Authority (NSW EPA), including the potential leaching of BPA and release of microplastics, we have proven Reconophalt™ brings no increased environmental risk compared to standard asphalt, while providing considerable sustainability and performance benefits.

In an Australian-first in 2020, Downer’s Reconophalt™ was approved for use in road construction by the NSW EPA under a Resource Recovery Order and Exemption.

In FY21, Downer’s Reconophalt asphalt received the world’s first cradle-to-grave lifecycle assessment for an asphalt product. Downer, with the support of the South Australian Department for Infrastructure and Transport, Green Industries SA and the R2P Alliance, has developed, independently verified and registered the Environmental Product Declaration (EPD) for Reconophalt.

In FY21, 15.7 per cent of total asphalt production in Downer was made up of recycled materials. This increased from 14 per cent in FY20. The consequent GHG emissions reductions are outlined in the chart below*.

This increase in FY21 was due to the nature of work undertaken on major roads, which allowed for an increase in recycled products to be used, specifically Reclaimed Asphalt Product (RAP).

For example, the Bruce Highway Upgrade project in Queensland installed a granulator to process RAP from the existing road and then fed it back into the new asphalt for the upgrade, delivering a complete closed-loop solution.

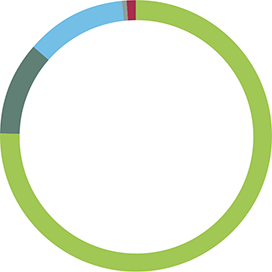

GHG emissions reductions from the use of recycled materials in asphalt production

* This chart displays the total GHG emissions reductions from the use of recycled products in asphalt production in FY21, with each of the specified recycled products represented as a percentage of total savings.