Waste management

The materiality assessment Downer conducted in 2021 reinforced that waste management is an important issue to Downer.

In FY20, Downer committed to setting waste targets for the FY21 period. However, after the interrogation of various data sources and engagement with Downer’s primary waste contractor, Cleanaway, it was deemed that Downer is not yet in a position to set an organisation-wide target. Instead, Downer has worked with Cleanaway to boost engagement on a targeted basis. This includes:

- Working with sites that have a low diversion rate and a high spend (and therefore high waste footprint)

- Conducting waste audits (effectiveness of implemented initiatives)

- Implementing collection optimisation programs.

Downer will use the results of each of these programs to inform meaningful targets across targeted waste streams in FY22.

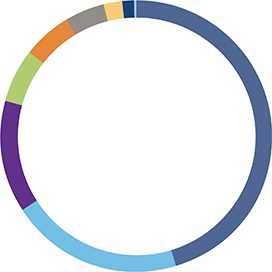

Breakdown of recycled waste (tonnes) by category

Comingled

994.20

Paper and cardboard

980.35

Metal

474.68

Clean fill

367.90

Timber

315.10

Organics

272.33

Construction

160.67

Plastic

64.35

Waste oil

61.56

eWaste

38.66

Glass

10.38

Flurotubes/globes

3.91

Ash

2.00

Breakdown of hazadous waste (tonnes) by category

In FY21, Downer continued to look for innovative solutions to reduce the amount of waste we generate through resource recovery, avoidance, reuse and recycling.

Downer is delivering the Denny Avenue Level Crossing Removal project as part of Perth’s METRONET program, which includes the replacement of the current Denny Avenue level crossing with a rail-over-road underpass at the nearby Davis Road.

Downer set proactive waste diversion targets for the project, including 85 per cent clean/inert excavation spoil diverted from landfill and 70 per cent other inert waste diverted from landfill. The team developed a Construction Resource Efficiency and Waste Management Plan to provide guidance on environmental issues and risks, control measures, contingency measures and monitoring requirements relating to waste management and resource consumption and resource efficiency for the project.

This plan helped Downer exceed its targets, achieving 99.9 per cent clean/inert excavation spoil diverted from landfill and 98.99 per cent other inert waste diverted from landfill. In addition, we also achieved 100 per cent green waste diverted from landfill.

All excavated spoil was classified onsite by the Downer Environment and Sustainability team. Once classified, the project utilised the services of waste specialists, Eclipse Soils, for processing the classified material for reuse at other locations across Western Australia. In addition to clean/inert excavation spoil, Downer was able to use this process to divert asbestos, Potential Acid Sulphate Soils (PASS) and hydrocarbon contaminated material to be treated and reused.

Construction and Demolition (C&D) waste (bricks, pavers, concrete, steel, timber and asphalt) was segregated and processed for reuse by several C&D recycling specialists across Perth. Reclaimed Asphalt Pavement (RAP) from the project was transferred to Downer’s Asphalt facility for reprocessing and reuse in asphalt pavements.

Downer is also committed to helping our customers improve their own waste management. For example, Spotless has assisted the Melbourne Cricket Club to achieve its sustainability goals by implementing a range of initiatives, including phasing out single-use plastics (plastic straws, stirrers, cutlery and plates) at EPICURE food outlets at the Melbourne Cricket Ground (MCG). Spotless also obtained approval from Victoria Police and the Victorian Commission for Gaming and Liquor Regulation to serve alcohol at the MCG in aluminium cans, rather than single-use plastic cups. The MCG previously used over 2.2 million plastic cups per year which ended up in landfill.

Spotless is also pioneering the use of GaiaRecycle dehydrators to reduce organic waste at many of the sites we operate at, including the MCG and Brisbane City Hall. Brisbane City Hall can produce up to 100 kilograms of food waste daily. We saw an opportunity to reduce organic waste going to landfill and introduced the GaiaRecycle food dehydrator, which turns food waste into compost. The machine breaks down and ferments food waste to reduce food volume by 85-90 per cent. The GaiaRecycle removes the moisture from the food waste, processes it at high temperatures to sterilise, and then cools the dry by-product so it can be used for soil amendment or enhancer for compost, which is then used at the surrounding Yarra Park in Melbourne and Brisbane Botanical Gardens and Roma Street Parklands.