Waste management

The materiality assessment we conducted in FY19 reinforced that waste management is an important issue to Downer.

We support the move towards a circular economy in a number of ways, including reducing the amount of waste we generate through resource recovery, avoidance, reuse and recycling.

Our commitment to waste management was further demonstrated in FY19, when Downer purchased a 50 per cent stake in Victorian waste resource company, Repurpose It, which holds the fundamental belief that all waste can be converted to valuable resources.

Last year, Downer committed to gathering baseline data for waste, and setting landfill reduction and diversion targets in FY21. Downer successfully established a baseline and is pleased to report waste data for the first time in FY20. Unfortunately, due to the impact of COVID-19 on the organisation, these targets were not set in the FY20 period.

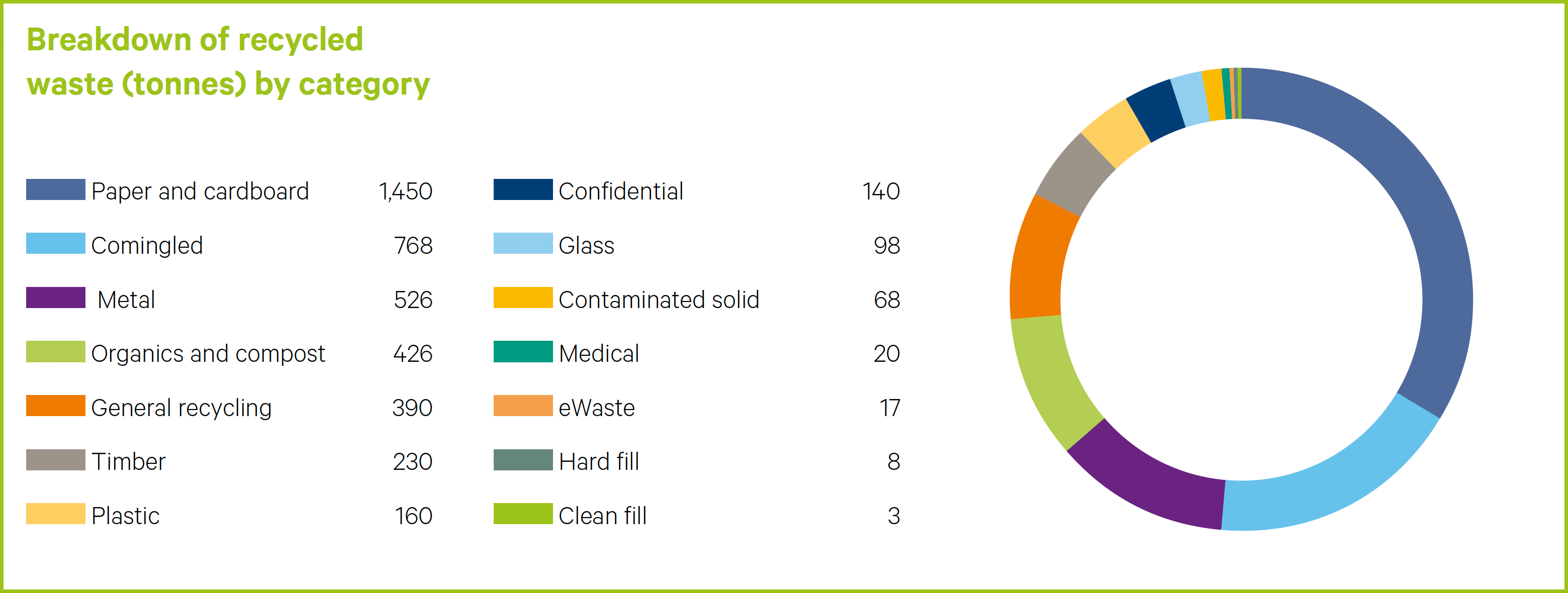

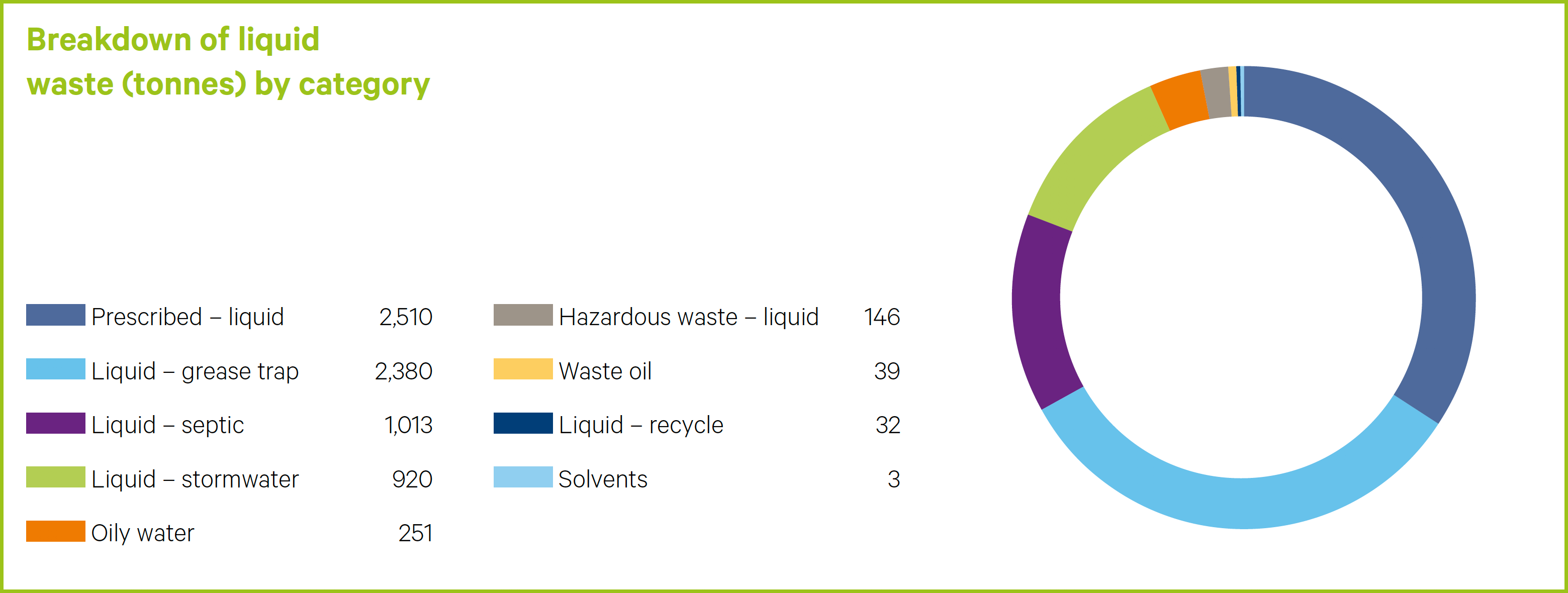

They will be set in early FY21 in order to drive performance improvement across the Group. Reporting the waste baseline is a major milestone for Downer and will allow us to measure our impact and track our overall landfill diversion rate for the first time. This revealed the following insights:

Cleanaway is Downer’s preferred waste management contractor in Australia. Downer and Cleanaway have agreed to ambitious key performance indicators to drive improved waste management practices and innovation that will ultimately reduce the amount of waste going to landfill. The KPIs consist of:

- Cleanaway dedicating a Resource Recovery Specialist to work only on Downer sites

- Quarterly National Contract Review meetings to include the Group Sustainability Manager

- Annual site visits (twice annually for sites with a spend greater than $100,000) to recommend improvement to waste practices and diversion, and offer innovation with site reports feeding into the Quarterly National Contract Review meeting

- Cleanaway to demonstrate improvements to waste practices and innovation to achieve an agreed dollar value saving per annum.

In FY20, Downer was in the process of setting targets, including those related to financial savings and waste diversion, in partnership with Cleanaway. This process included:

- Review of average bin weights across the organisation. It was identified that 553 general waste bins were either over-serviced, oversized or contained significant amounts of cardboard, LDPE film or EPS. The remediation of these issues resulted in improvements in waste diversion as well as significant cost savings

- Identification of roller packers for Rollingstock Services sites. Once fully implemented, this should result in cost savings of approximately $800,000. This reduces the number of bins required, thereby reducing the number of trips required to transport waste to sorting facilities. Consequently, transport emissions associated with transporting fuel also reduces.